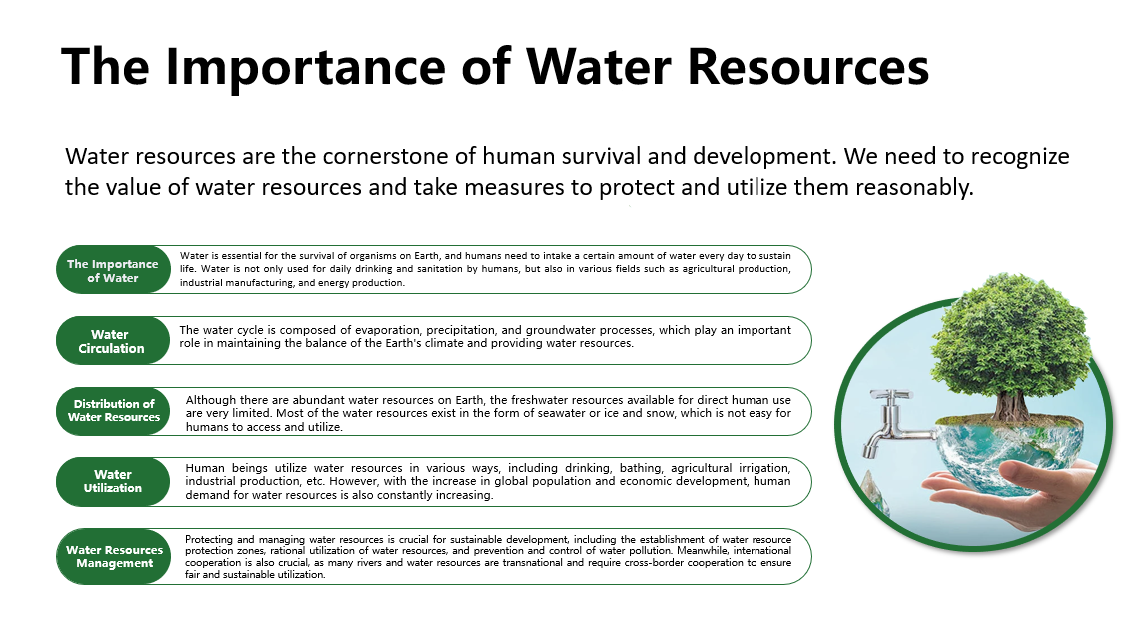

Water Resources Management

Wistron's are largely assembly-based, with service locations mainly responsible for repairs and storage. As such, Wistron operations have little demand for water use. Most of our water demand derives from domestic use and plant equipment such as kitchens and cooling towers. Our evaluations confirm that our source of water for plants and offices is tap water, which amounts to not obvious environmental impact on water resources and the eological environment of water sources. Nevertheless, Wistron still actively collects water consumption data and regularly monitors water quality and consumption conditions. We organize water conservation campaigns from time to time and water anagement training for the purpose of protecting water resources.

Wistron’s management of water resources can be divided into “water resource management and daily water conservation” and “water recycling and wastewater management.” We took stock of high-risk areas for water resources based on n evaluation of the water stress indicators of our global operations. We then implement preventive measures based on the water resource management strategy. Dedicated units in different plants are responsible for water resource management, plan formulation and implementation, regular monitoring, resolution of irregularities, data analysis, and continuous improvements. Wistron is committed to rigorous compliance with national water regulations, reasonable water use, giving priority to water-efficient equipment, and using energy-efficient panels to monitor water consumption and improve water use efficiency.

Wistron's water target in 2024 is to reduce water consumption intensity by 13% from 2022 and set more ambitious goals for medium- and long-term while continuing to track and disclose the water conservation outcomes each year.

Water Consumption

Unit: Million cubic meters

| Type |

2021 |

2022 |

2023 |

2024 |

| Total Water Withdrawal |

4.09 |

3.81 |

2.63 |

2.49 |

| Total Water Discharge |

3.23 |

3.02 |

2.03 |

1.95 |

| Total net fresh water consumption |

0.86 |

0.79 |

0.60 |

0.54 |

| Recycled & Reused Water |

0.37 |

0.29 |

0.16 |

0.06 |

- Notes 1:Total net fresh water consumption target in 2024 was 0.81 million cubic meters.

Water Usage Performance Indicators

| Type |

Unit |

2021 |

2022 |

2023 |

2024 |

| Water Usage per Unit-revenue |

kilotons of water / NT$ 1B |

6.3 |

5.6 |

4.0 |

3.6 |

| Water Recycling Rate |

Percentage (%) |

8.9 |

7.7 |

6.3 |

2.3 |

- Notes 1:2024 performance indicators are based on water withdrawal/Wistron Group revenue from Wistron and subsidiaries listed in consolidated financial statements (excl. Wiwynn and its subsidiaries).

- Notes 2:Figures for other years were tallied according to the disclosure boundaries from respective sustainability reports.

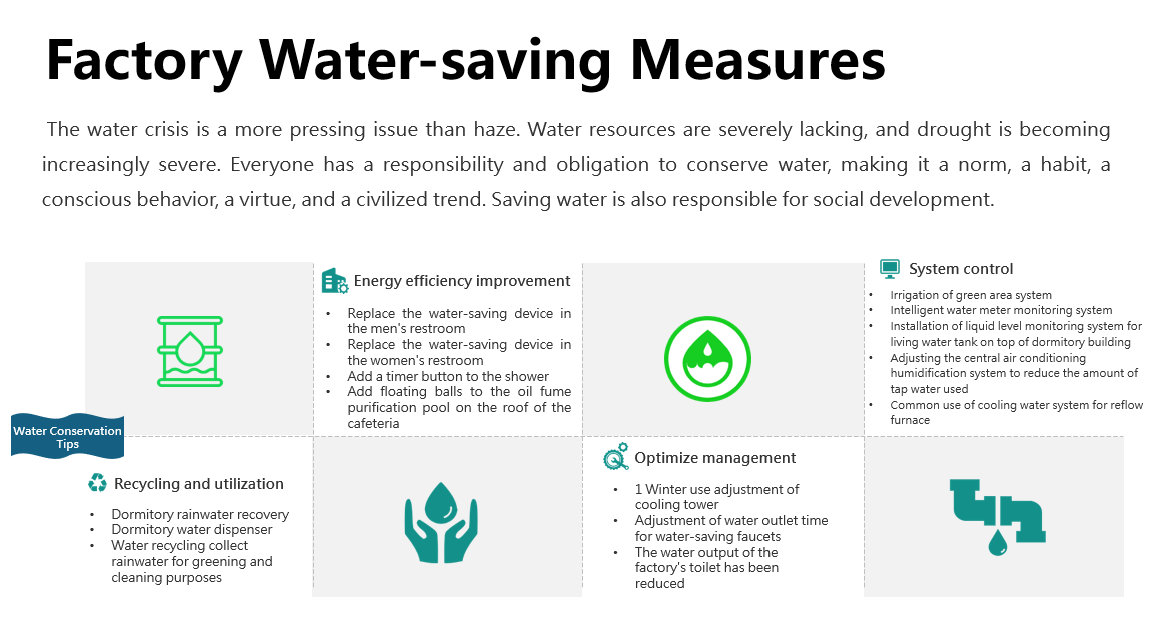

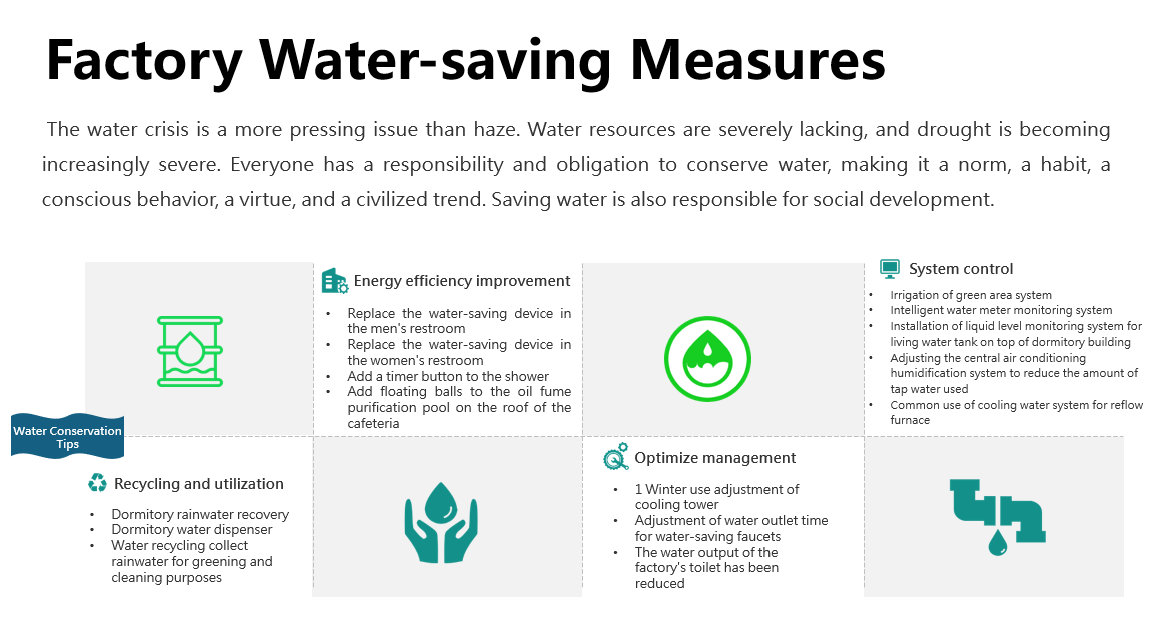

Actions and Results

01 | Reduce water consumption

To implement the water conservation policy, Wistron set the 2024 water conservation target to reduce water intensity by 13% compared to 2022. Through water resource management and daily water-saving policies, water conservation projects were divided into daily water-saving, recycling, and management. In 2023, the total water saved amounted to approximately 182,664.84M³, reducing water intensity by 36% compared to 2022. Although Wistron's water use is primarily for domestic purposes, the company actively improves water resource utilization efficiency, achieves water conservation goals, saves costs, and promotes sustainable development.

| Type |

Actions |

Annual Water Savings (M3) |

| Daily Water Savings |

Water supply regulation in domestic water use zones |

5,515.70 |

| Recycling |

1. Greywater reuse with RO systems

2. Rainwater recycling |

64,914.00 |

| Management Wate Savings |

1. Patrol management

2. Adopt water management & control systems |

112,235.14 |

| Total |

182,664.84 |

02 | Water Recycling Practices and Wastewater Management

Water Recycling Practices

Effective water management can significantly reduce a company's water usage, decrease reliance on natural water bodies, and reduce dependency on aquatic ecosystems. Wistron’s water recycling mainly involves public facilities and process-related management, including air conditioning condensate recovery, RO wastewater recovery, and process RO wastewater reuse. These efforts actively enhance the use of water resources across global manufacturing plant.

Wastewater Management

Wistron strictly adheres to regulatory requirements and internal standard procedures at all operational sites to manage wastewater effectively through proper treatment facilities. Wistron's primary wastewater management is divided into domestic water and process water. Domestic water is treated through primary, secondary anaerobic ponds, and clarifiers before being discharged through outlets, ensuring compliance with regulations. Some plants generate process wastewater during production, which is treated through collection tanks and reaction tanks before being discharged into local designated sewage pipelines and sent to local designated Sewage treatment plants for unified treatment.

03| Water Stress Index

According to the World Resources Institute (WRI) Aqueduct tools, Wistron’s locations in Jiangsu Province (China) and Mexico are categorized as having “extremely high” baseline water stress. These high-stress regions account for approximately 7.7% of Wistron’s total water withdrawal.

| Water Consumption in High Water Stress Regions |

| Region |

Jiangsu Province (China) |

Chihuahua (Mexico) |

| Plants |

Wistron Automotive Electronics Plant |

Mexico Plant |

| Water Withdrawal (M3) |

85.70 |

106.07 |

| Percentage of Revenue (%) |

0.6 |

| Percentage of Water Withdrawal (%) |

7.7 |

- Notes 1: Revenue percentage derived from 2024 data on the Market Observation Post System