【Green Products】Nature-based Solutions Empowers Wistron’s Commitment to 100% Recycled Materials on Product Packaging

To contribute to biodiversity, anti-deforestation, and soil conservation, Wistron requires all suppliers of critical packaging materials and non-tier 1 value chain suppliers to acquire FSCTM CoC (Chain of Custody) certification. In 2023, we were able to develop a cardboard box using 100% FSC-certified papers and replace PE plastic bags with 100% recyclable materials. When shipping products, disposable packaging materials and excessive packaging is often used, causing unnecessary waste and more trash. As such, Wistron and suppliers have worked together to replace desiccant packs with anti-tarnish paper to reduce the weight of packaging materials as well as ensure that the bursting strength of cardboard boxes meets the bearing capacity to reduce its weight by 8%. As a result, we were able to reduce waste by 11,590 kg in 2023, fulfilling our goals of reducing plastic use and the use of natural resources.

Expand Green Innovation Design & Product Program & Increase Use of Green Recyclable Materials

To extend the lifecycle of products and enhance repairability, Wistron aims to reduce the extensive use of screws and simplify wiring designs. This enables quick disassembly and repair with basic tools, reducing maintenance time by approximately 1.5 hours. This design concept has been successfully implemented in 16-inch laptops, desktop computers, and monitors. Additionally, priority is given to raw materials with the lowest environmental impact to reduce our consumption of natural resources. For example, in the case of the metal mechanical structural of 27-inch monitors, we use steel containing 50% recycled material. In addition, we opt for electric arc furnace instead of traditional blast furnaces to reduce carbon emissions by 40%, thus embodying the development philosophy of green product innovation.

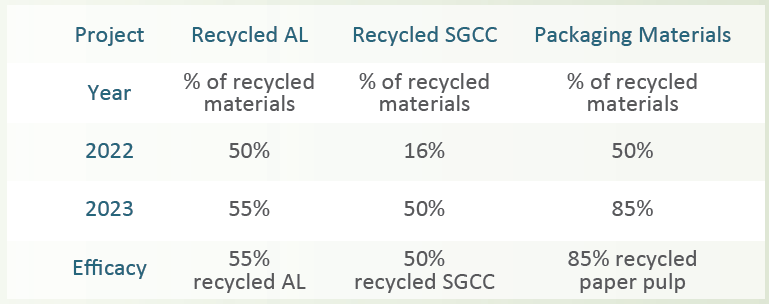

Design Stage Recycled Materials

In 2023, we started using 55% low-carbon recycled

aluminum and 50% recycled galvanized steel plates

(SGCC) for electronic products. For packaging materials, we used 85% recycled paper pulp. The high percentage of recycled material used ensures that we can reduce resource consumption and practice circular designs.

Manufacturing Stage Smaller Sizes

To effectively reduce product carbon footprint, we

introduced TK2 advanced process technologies into

motherboard designs, enabling us to fit more components in a small surface area. This allowed us to successfully replicate our 13-inch laptop PCB design to PCBs for larger monitors, reducing surface area by 17.4%.

Disposal Stage Quick Assembly & Disassembly

To achieve automatic checking, maintenance, repairs, and replacement for components across all production lines, we’ve expanded modular designs to desktop computers and our 27-inch monitor. This has successfully reduced assembly time by 80%, reducing manpower and energy consumption throughout the assembly stage.