Waste Management

Wistron is committed to avoid banned substances or materials and actively promotes waste reduction, recycling, and reuse. Any materials and suppliers we work with are rigorously and carefully screened, and we continue to pursue technical improvement or eco-friendly materials. We abide by environmental and customer regulations related to our activities, products, and services to attain, or even exceed set goals. Waste management at Wistron consists of "consistent waste classification and reduction" and "recycling and reuse." We comprehensively evaluate and check the generation and flow of waste and toxic substances through sound waste and hazardous substance management, minimizing waste as much as possible through recycling. Strong management over waste and hazardous substances can help reduce the impact and burden on the environment, but also enable Wistron to create niches in business operations with improved material usage and lowered operating costs, helping us achieve sustainability.

Wistron identifies waste types and reduction opportunities through management processes such as source reduction, recycling, and reuse, ensuring waste is reasonably recycled, utilized, and disposed of, thereby reducing its environmental impact. This not only minimizes environmental impact and burden but also reduces operational costs by improving material utilization, creating a competitive edge that benefits the company's sustainable operations.

Three Core Principles of Waste Management:

- Waste Review: Assess production processes and analyze waste generation points at each step of production. Then, confirm waste disposal according to regulatory requirements.

- Reuse & Recycle: Leverage the review process to identify opportunities to reduce waste. Also, develop a comprehensive recycling system to ensure waste can be effectively recycled and reused. Lastly, explore ways to reuse waste, e.g., apply waste materials to other production stages or develop new products using waste materials.

- Monitoring & Assessment: Continue to monitor and collect data on waste generation and processing. Also, regularly assess the impact of waste reduction measures to uncover opportunities for improvement.

Investment in innovation or R&D to minimize waste

Product Design

Wistron is dedicated to the research and development, design, manufacturing, and service of its products. Sustainable product design and development are based on the concept of the life cycle, considering aspects from raw material acquisition, manufacturing, distribution, product use, to waste recycling. This approach aims to reduce the environmental impact of products, create sustainable value, ensure the sustainable use of resources, and establish a green circular sustainable business model. During the product design and development phase, guidelines and review procedures for green product design are implemented, considering waste disposal and recycling from the design stage to minimize the impact on people and the environment after the product's disposal.

Product Manufacturing - End-of-Life Management

The ESG teams at Wistron's manufacturing locations are actively driving in-plant waste reduction and management through the following measures:

- Engage with waste treatment vendors and prioritize those with Zero Waste to Landfill accreditation to increase water recycling or reuse, thereby raising our recycling rate.

- Assess and adopt waste reduction technologies:

- Work with R&D personnel in plants to uncover source reduction opportunities, e.g., optimizing the use of sheet materials to reduce waste trimmings.

- Actively reach out to suppliers to adjust packaging specifications or methods to reduce packaging from raw materials.

Amount of Waste Generated

| Disposal Method |

2021 |

2022 |

2023 |

2024 |

| Non-hazardous |

a. Reuse |

238.07 |

232.67 |

491.15 |

346.00 |

| b. Recycle |

35,533.31 |

35,058.21 |

27,818.53 |

32,897.68 |

| c. Replaced with alternative raw materials |

- |

- |

- |

- |

| d. Landfill |

562.67 |

1,506.32 |

1,127.89 |

1,370.04 |

e. Incinerate

(with energy recovery) |

1,670.37 |

2,300.53 |

1,154.75 |

1,356.36 |

f. Incinerate

(without energy recovery) |

255.31 |

- |

32.00 |

45.97 |

| g. Other treatment |

- |

- |

- |

873.45 |

| Subtotal |

38,259.73 |

39,097.73 |

30,624.32 |

36,871.51 |

| Hazardous |

h. Temporary storage |

- |

- |

- |

- |

| i. Transported to external treatment facilities_Recycle |

- |

- |

669.17 |

948.92 |

| j. Transported to external treatment facilities |

1,043.50 |

1,205.56 |

533.92 |

477.56 |

| Subtotal |

1,043.50 |

1,205.56 |

1,203.09 |

1,426.48 |

| Total |

Total waste generated (d.+e.+f.+g.+h.+j.) |

3,531.85 |

5,012.41 |

2,848.56 |

4,123.38 |

| Total waste recycled/ reused (a.+b.+c.+i.) |

35,771.38 |

35,290.88 |

28,978.85 |

34,174.61 |

Waste reduction

To reduce waste more effectively, Wistron shifted the waste treatment target to "waste intensity reduction" starting from 2021. Using 2018 as the base year, we strive to reduce waste generation intensity (waste generation per unit revenue) by 2% each year – which means a 8% reduction by 2024, a 20% reduction by 2030, and a 30% reduction by 2035.

With our waste management processes, waste reduction and separation efforts are classified into three main focuses: reuse, recycle, and repurpose. These end-of-life treatment aim to increase waste conversion and reduce landfill rates:

- Reuse: Analyze opportunities for waste reuse and collaborate with suppliers to promote reuse of packaging materials. For example, reusing pallets, plastic boxes/packaging materials, or cardboard boxes in plants.

- Recycle: Engage with waste treatment vendors to increase waste recycling rates. For example, plastics, waste cardboards, kitchen waste, etc.

- Repurpose: Repurpose waste materials into other materials.

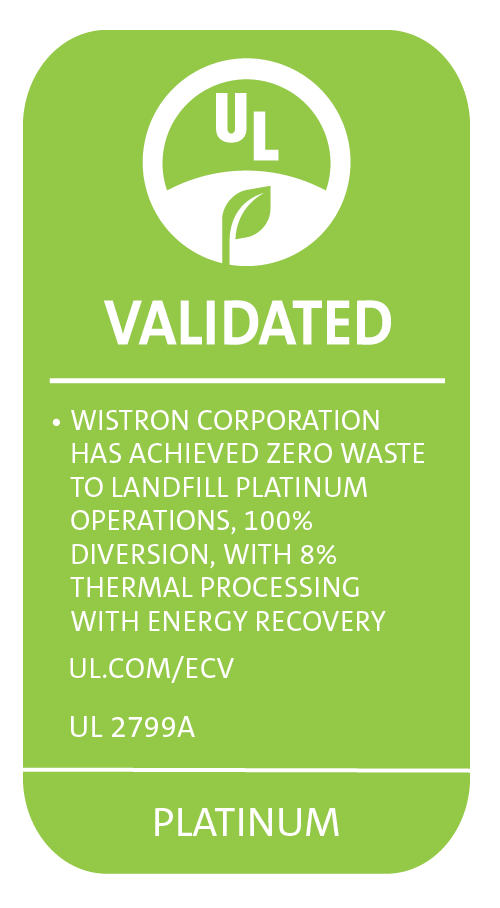

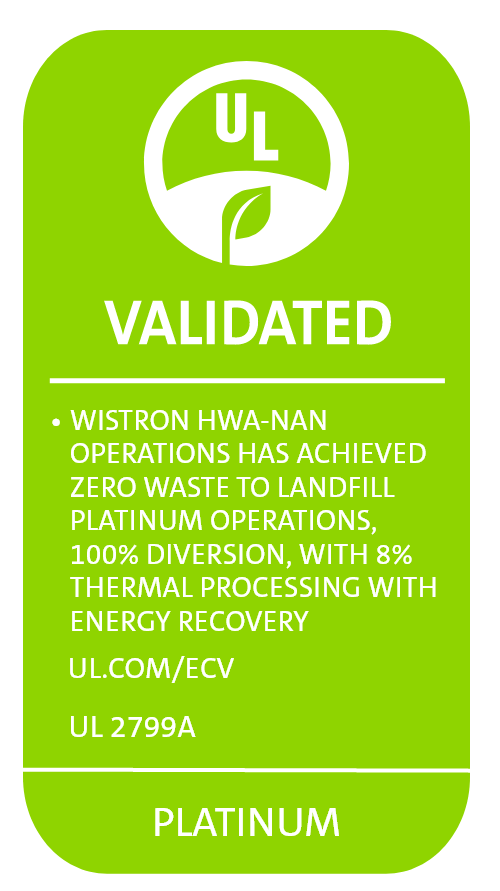

Through these three major actions, combined with regular environmental education and advocacy, and in conjunction with the UL2799 Zero Waste to Landfill certification planning and actions, Wistron recycled, reduced, and reused 1,848.56 metric tons of waste, reducing waste intensity by 11% from 2018 levels, achieving three platinum-level and one gold-level Zero Waste to Landfill certifications.

International Certification Promotion - Zero Waste to Landfill

Wistron has introduced the UL 2799 waste zero landfill certification mechanism in all major manufacturing plants since 2022. Our widespread adoption of UL 2799 aims to identify waste reduction plans and optimize resource utilization to achieve a sustainable resource cycle. At Wistron, we continue to expand our zero-waste mission, sharing our experiences in zero landfill waste certification with overseas plants to realize our commitment to sustainable management.

Waste Recycling Rate

| Item |

2021 |

2022 |

2023 |

2024 |

| Non-hazardous |

Reuse |

0.6 |

0.6 |

1.5 |

0.9 |

| Recycle |

90.4 |

87.0 |

87.4 |

85.9 |

| Replaced with alternative raw materials |

0.0 |

0.0 |

0.0 |

0.0 |

| Incinerate (with energy recovery) |

4.3 |

5.7 |

3.6 |

3.5 |

| Hazardous |

Recycle |

- |

- |

2.1 |

2.5 |

| Total |

95.3 |

93.3 |

94.7 |

92.8 |

Waste Management Performance indicators

| Performance Indicators |

Unit |

2021 |

2022 |

2023 |

2024 |

| Waste per unit-revenue |

kilotons of waste output/

NT$ 1B |

0.061 |

0.059 |

0.048 |

0.056 |

| Non-hazardous waste output per unit-revenue |

kilotons of waste output/

NT$ 1B |

0.059 |

0.057 |

0.046 |

0.054 |

| Hazardous waste output per unit-revenue |

kilotons of waste output/

NT$ 1B |

0.002 |

0.002 |

0.002 |

0.002 |

- Notes 1: Given the report's disclosure boundaries, waste intensity in 2018 has been adjusted to 0.062 kilotons / NT$1B.

- Notes 2: 2024 performance indicators are based on waste generation/Wistron Group revenue from Wistron and subsidiaries listed in consolidated financial statements (excl. Wiwynn and its subsidiaries)

- Notes 3: Figures for other years were tallied according to the disclosure boundaries from respective sustainability reports

Co., Ltd-Zero waste-Green-Tier.png)

-Zero waste-Green-Tier.png)