Supply Chain Sustainability Management

Wistron has established a comprehensive sustainable supply chain management process that consists of five core steps: adherence to sustainability norms, sustainability risk assessment, sustainability assessment, improvement and capability building, and preference and exclusion mechanism. This process is designed to ensure that all suppliers fully comply with the requirements of the Supplier Code of Conduct and effectively avoid potential ESG-related conflicts. Through systematic risk assessments and audits, Wistron works closely with suppliers to verify implementation, provide guidance on areas for improvement, and assist in developing action plans. In addition, Wistron actively promotes economic inclusion and resilience-building among suppliers. Through long-term collaboration, we aim to enhance suppliers’ sustainability performance and further solidify Wistron’s critical role and impact within the supply chain.

- Supplier sustainability management structure

.JPG)

Compliance with Sustainability Standards

Supplier code of conduct

In advancing corporate sustainability, Wistron recognizes the critical impact of supply chain management on both society and the environment. To this end, Wistron has established a Supplier Code of Conduct as a foundation for supplier action in sustainability practices. This Code is aligned with the Responsible Business Alliance (RBA) Code of Conduct and the United Nations Guiding Principles on Business and Human Rights, covering five core areas: labor rights, health and safety, environmental protection, ethics, and management systems. The Code also includes specific requirements related to biodiversity, the prevention of deforestation, and land conservation, aiming to holistically enhance the sustainability of the supply chain. Wistron also incorporates the level of supplier compliance with the Code as a key evaluation criterion in procurement decisions to ensure alignment between supply chain partners and the Company’s sustainability goals. In 2024, 100% of Wistron’s suppliers signed the Supplier Code of Conduct, demonstrating their full recognition of and commitment to Wistron’s sustainability standards. In addition, depending on the supplier category, Wistron further required the signing of the letter of agreement, the declaration of controlled hazardous substances confirmation and compliance, and the declaration of non-use of conflict minerals, all of which also achieved a 100% signing rate. These measures have not only strengthened Wistron’s governance capabilities within the supply chain but also promoted a shared commitment among partners to uphold higher standards of social and environmental responsibility.

- Signing of the Supplier Code of Conduct

| Year |

2024 Performance |

2024 Targets |

| Existing suppliers |

Number of suppliers required to sign |

1,338

(cumulative) |

- |

| Percentage of signed suppliers(%) |

100 |

100 |

| New suppliers |

Number of suppliers required to sign |

2 |

- |

| Percentage of signed suppliers(%) |

100 |

100 |

Wistron supplier code of conduct

Sustainability Risk Assessment

In order to assess sustainability risks within the supply chain, Wistron conducts a two-phase risk investigation on suppliers. Through varying requirements at different stages, we aim to evaluate suppliers’ ESG performance and identify potential risks within the supply base. The first phase focuses on comprehensive risk screening, while the second phase further identifies high-risk suppliers. For high-risk suppliers identified through the assessment process, Wistron initiates an assessment procedure, combining professional guidance with support to help suppliers develop and implement improvement plans. This approach enables effective control at the source of risk and helps reduce overall sustainability risks within the supply chain.

Active Assessment Target: All suppliers

To identify potential risks within the supply chain, Wistron conducts preliminary assessments and screening of suppliers. The evaluation covers multiple dimensions, including environmental, social, and governance (ESG) performance, business relevance, country or region of operation, industry type, and product characteristics. Through this process, suppliers with potential risks are preliminarily identified and brought under management to reduce overall supply chain risk.

Risk Assessment Scope : Tier 1 and Non-Tier 1 Suppliers

To comprehensively understand the sustainability risks of existing suppliers, Wistron distributes a Sustainability Risk Self-Assessment Questionnaire to both Tier 1 and non-Tier 1 suppliers, requiring them to provide supporting documentation to gain deeper insights into their sustainability risks and management practices. The questionnaire covers five key sustainability dimensions: sustainability and operational risk management, supply chain and business continuity, environmental protection, human rights and labor protection, and occupational safety and health. Through this mechanism, Wistron is able to identify and manage sustainability risks across the supply chain and mitigate potential risks.

Suppliers with a score of less than 80 are defined as high-risk suppliers. In 2024, a total of 9 high-risk suppliers were identified. According to the results, the main sustainability risk factors in 2024 were concentrated in the areas of environmental protection and sustainability and operational risk management. In order to effectively mitigate the impact of these risk factors, Wistron will prioritize greenhouse gas inventory and certifications (ISO 50001 and ISO 14064-1) for critical and high-energy-consuming material suppliers, in addition to promoting the purchase of renewable energy certificates. Other identified risk factors will be listed as items requiring guidance for remediation through assessment and improvement programs.

Sustainability Assessment

To comprehensively assess the implementation of sustainability practices among suppliers, Wistron adopts a diversified assessment approach, including both desk assessments and on-site assessments. On-site assessments are further categorized into 2nd party assessments, 3rd party assessments, and assessments conducted in accordance with industry standards. Wistron has also established annual targets and a long-term goal for 2030, providing clear direction for promoting sustainability in the supply chain over both the short and long term, thereby enabling continuous progress toward these objectives.

Corrective action/improvement plans

To enhance the sustainability performance of suppliers, Wistron provides counseling measures for deficiencies identified in assessments, including on-site and remote support to assist suppliers in developing and implementing improvement plans. If the supplier is unable to complete the improvements within two months, they may submit another assessment application for a second assessment to confirm the implementation of the improvement plan. However, if a supplier fails to pass the second assessment, they must wait six months before reapplying. During this period, Wistron will evaluate the feasibility of using alternative materials or consider replacing the supplier. If immediate substitution is not feasible due to urgent supply requirements, the replacement will proceed once an alternative is in place. For suppliers unable to meet improvement requirements within two years, Wistron will gradually reduce procurement volume until the partnership is terminated or the supplier is disqualified. In 2024, all assessed suppliers completed the required improvements within the specified timeframe, and no partnerships were terminated due to non-compliance..

- Proportion of deficiencies

.JPG)

- Supplier assessment corrective/improvement actions

Preference and Exclusion Mechanism

To encourage suppliers to implement sustainable practices and enhance their sustainability performance, Wistron conducts sustainability performance evaluations of suppliers and implements a preference and exclusion mechanism in accordance with relevant management procedures.

- Preference : Suppliers with outstanding sustainability performance ratings are prioritized as primary suppliers, receive higher order allocations, and are granted opportunities to participate in new projects. They are also recognized and honored as Outstanding Suppliers during the annual Partner Conference, with a total of 11 suppliers recognized in 2024. In 2024, a total of 6 suppliers received increased orders due to the preference mechanism.

- Exclusion : Suppliers with poor sustainability performance ratings have their eligibility for new project introductions suspended and their procurement amounts reduced. If a supplier fails to improve their performance within a two-year period, their procurement is halted, and their supplier status is revoked. In 2024, no suppliers met the criteria for exclusion.

Supplier Sustainability Evaluation

ToWistron has established ESG-related thresholds for all suppliers, including both new and existing ones. To become a qualified Wistron supplier, vendors are required not only to sign the Code of Conduct but also to obtain certifications such as ISO 9001, ISO 14001, IECQ QC 080000, and ISO 45001.

For new suppliers, Wistron conducts evaluations using the supplier quality system evaluation form, in which ESG factors account for 13.33% of the total score. These factors include:

1.Establishing appropriate and effective documents and procedures related to the RBA Code of Conduct

2.Compliance with labor standards

3.Compliance with health and safety standards

4.Compliance with environmental standards

5.Compliance with ethics business standards

6.Compliance with management systems

Wistron evaluates the ESG performance of existing suppliers through the supplier performance evaluation. Evaluation criteria include supplier’s quality, reliability, compliance, supply capability, price, and ESG sustainability performance. Among these, ESG factors account for 20% of the total score and include:

1.Quarterly reviews of ESG sustainability activities

2.Annual review of ISO 14064-1 certification

3.Annual review of ISO 50001 certification

4.Annual ESG sustainability audit score

5.Major Missing Events of ESG Sustainability On-site Assessment

ESG risk management and mitigation plans (Human Rights: Whether the supplier conducts human rights risk

assessments and if there are any reported human rights violations. Operational Risk: Whether the supplier provides

financial statements or key financial indicators, and whether related risks are disclosed or addressed. Disaster

Preparedness: Includes fire safety and natural disaster readiness.)

Capacity Building

Buyer Education Training

Procurement-related departments (including buyers, logistics, quality assurance, and other supply chain functions) are equipped to understand supplier management processes and their roles in sustainability. Educational training is a key element of corporate sustainable development. Through systematic courses, procurement staff enhance their understanding of environmental, social, and governance (ESG) issues, including the prohibition of forced labor (such as slavery or human trafficking). The training further focuses on building sustainability-related competencies tailored to core procurement functions, enabling staff to incorporate ESG strategies into daily operations and supplier engagement. In 2024, Wistron collaborated with the ESG Sphere Course Review Committee to develop a series of ESG-related online training modules. A total of 2,170 individuals were trained, amounting to 1,497 hours of education.

Supplier Education Training

To support suppliers in adopting ESG-aligned strategies and actions in their operations—and to strengthen the overall resilience and sustainability of the supply chain—Wistron continues to offer relevant training through its online supplier education platform. These courses aim to enhance suppliers’ understanding of sustainable development practices and reinforce partnerships based on shared ESG values. In addition to the mandatory annual training on the Supplier Code of Conduct, a new required course—Introduction to ISO 14064-1—was introduced this year to raise awareness of energy conservation and carbon reduction. A total of 404 Tier-1 suppliers completed the training, achieving a 100% completion rate.

Partner Conference and Sustainability Sharing Forum

In 2024, Wistron continued to center its efforts around Resilience – Challenges & Opportunities. At the Wistron Group Partner Conference, the company shared its achievements in sustainable resilience and its roadmap toward emission reduction targets. Leveraging the "big leads small" effect, Wistron guided its supplier partners in progressing toward the net-zero goal. The company also recognized and honored suppliers who demonstrated outstanding performance in sustainability and a strong commitment to integrity. Through these efforts, Wistron aims to cultivate a spirit of collaboration, mutual benefit, and sustainable growth across its business ecosystem.

To promote supplier engagement, Wistron hosted two Supplier Sustainability Sharing Forums in 2024:

- First forum: Topics included the RBA (Responsible Business Alliance) Code of Conduct and case studies, corporate carbon management and greenhouse gas inventory, product carbon footprint verification, and an introduction to energy management systems. Wistron also presented its sustainability management policies and communicated its requirements on anti-corruption, GHG inventory, and water risk management. In addition, the company introduced its supplier sustainability survey systems. More than 15 leading electronics suppliers shared best practices and case studies on energy-saving technology upgrades and carbon reduction measures. These exchanges aimed to help suppliers better understand the current state of industry sustainability and enhance their motivation to engage in sustainable development. A total of 283 suppliers participated.

- Second forum: The then Vice President of Intel and General Manager of Intel Taiwan was invited to share insights on “How Companies Can Build a Workplace with diversity, equity, and inclusion (DEI)”, helping suppliers understand how to foster a diverse and inclusive corporate culture. A total of 28 suppliers participated.

.

Capacity Building Project: Promoting Net Zero Carbon in the Sustainable Supply Chain

- Establishing a segmented supplier carbon management promotion strategy

Starting from 2021, annual greenhouse gas inventory results from suppliers are collected. Upon analysis, it was found that suppliers exhibit varying degrees of capability in carbon inventory and reduction. Consequently, a classification management system has been implemented, categorizing suppliers based on their level of significance (determined by factors such as revenue and material substitutability) and carbon inventory capabilities. Tailored project plans are provided to suppliers in different categories, along with necessary assistance resources, experience-sharing courses, and consulting resources, to ensure their progressive advancement towards carbon neutrality.

.JPG)

- Building supplier carbon management sustainability capabilities

Wistron conducted a comprehensive inventory of Scope 3 greenhouse gas emissions across all 15 categories, with results indicating that upstream raw material procurement accounts for the highest share of emissions. In response, Wistron launched a carbon management capacity-building program tailored to different categories of suppliers. The program covers carbon inventory training, verification mechanism enhancement, the introduction of Science Based Targets (SBTi) initiative emission reduction targets, and collaborative carbon reduction projects. In 2024, Wistron initiated four carbon management projects and engaged in in-depth collaborations—lasting over six months—with 206 significant suppliers, continuously enhancing the carbon management capabilities of supply chain partners and jointly advancing emission reduction targets.

- Supplier capability building KPI

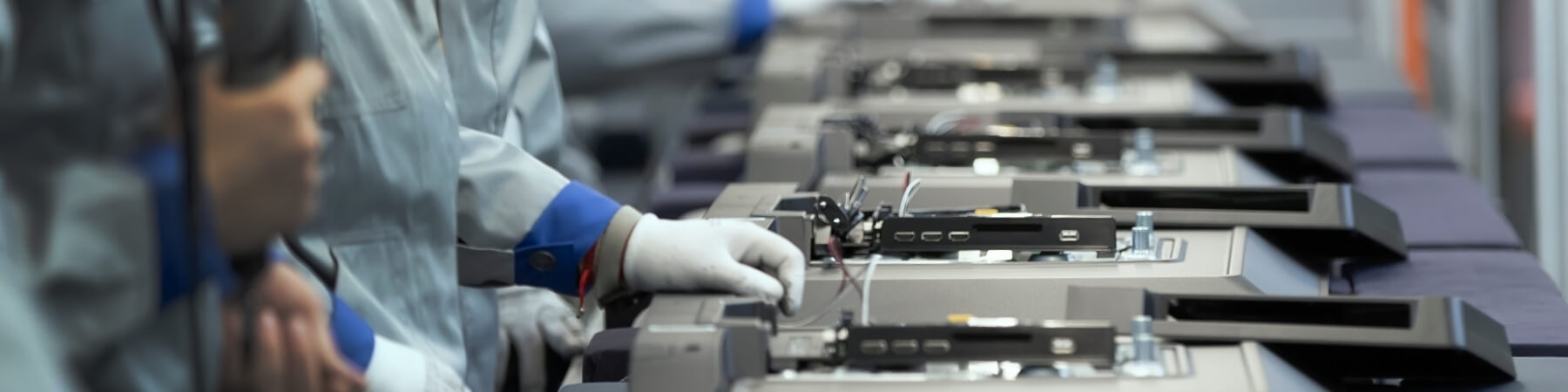

Green Supply Chain Management

A green, transparent, and circular supply chain encompasses all the essential elements of a modern, sustainable supply chain. Wistron’s green supply chain management covers the following aspects:

- Green Design: Incorporates RoHS and Product Carbon Footprint (PCF) standards at the design stage to ensure environmental compliance.

- Green Procurement: Prioritizes eco-friendly materials and certified suppliers to reduce carbon footprint.

- Green Manufacturing: Partners with low-carbon suppliers to implement carbon reduction strategies and promote sustainable production.

- Green Packaging: Reduces and reuses packaging materials while ensuring reliability. Prioritize suppliers with Forest Management (FM) and Chain of Custody (CoC) certifications for shipping materials to ensure sustainable sourcing.

- Green Transportation: Utilizes low-emission, energy-efficient, and smart logistics solutions to support carbon reduction.

- Green Recycling: Promotes the use of recycled plastics and EPE; encourages reuse and resale of inventory to minimize waste. Reuse excess inventory and facilitate resale to reduce stock levels and minimize waste.

These measures ensure that every stage of the green supply chain meets environmental standards and supports the company’s progress toward sustainable development goals.

Supplier Circular Economy Project Cooperation

Amidst the global push for a circular economy, Wistron remains committed to safeguarding natural life and forests by fostering communication and collaboration with suppliers. This focus enables the fulfillment of biodiversity and non-deforestation pledges, while simultaneously reducing the Earth's environmental burden. Furthermore, it enhances suppliers' sustainability awareness and capabilities to adapt to evolving sustainability trends.

.JPG)

.JPG)

.JPG)

.JPG)