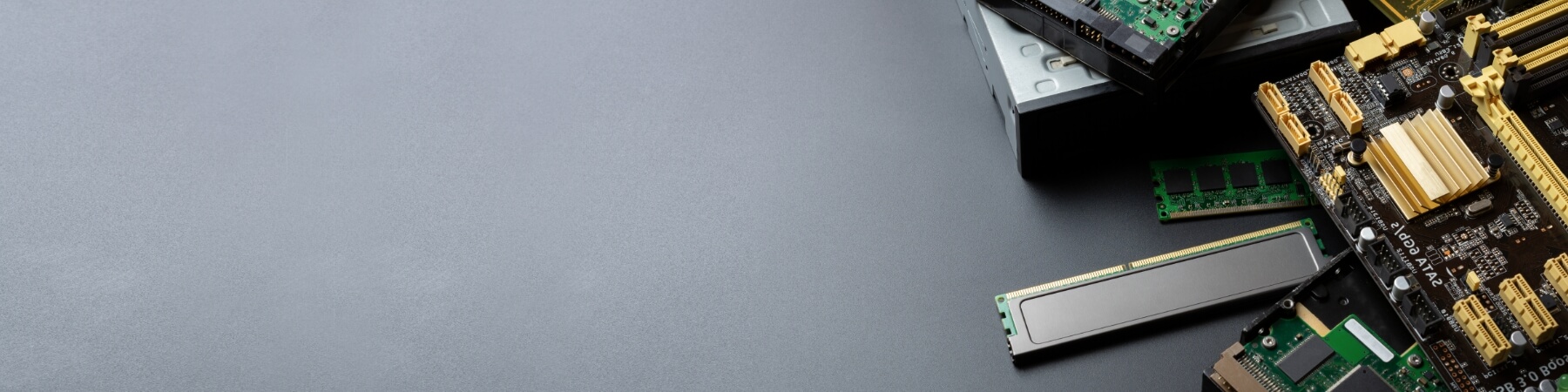

Sustainable Materials

Global resources are finite. As technology advances, human activity inevitably places increasing pressure on ecosystems and societies. At Wistron, the manufacturing of our products relies on a variety of raw materials. Only by committing to the use of sustainable materials will we be able to reduce environmental and social impact. As such, we have established a Sustainable Materials Policy, set corresponding goals, and launched related programs. In line with this policy, we assess the environmental and social impacts of our R&D, procurement, production, operations, and services, prioritizing the use of primary or secondary raw materials with the least negative impact.Wistron's Definition of Sustainable Materials:

- Compliant Hazardous Substance Management Regulations

- Free from conflict minerals

- Made from recycled or renewable sources

- Sourced outside of ecologically protected areas

- Support environmental conservation and avoid human rights violations