【Recycling】Lithium Battery Black Mass Recycling Equipment Circular Economy Developed, Refined Recycling Technology

2024.06.28

Special Report on Sustainability

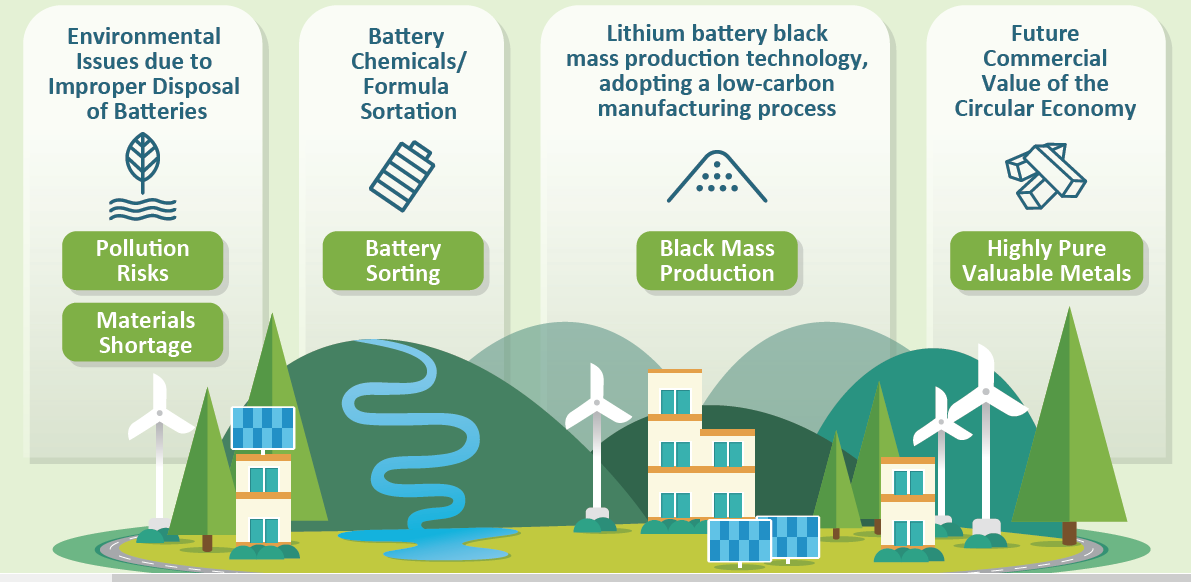

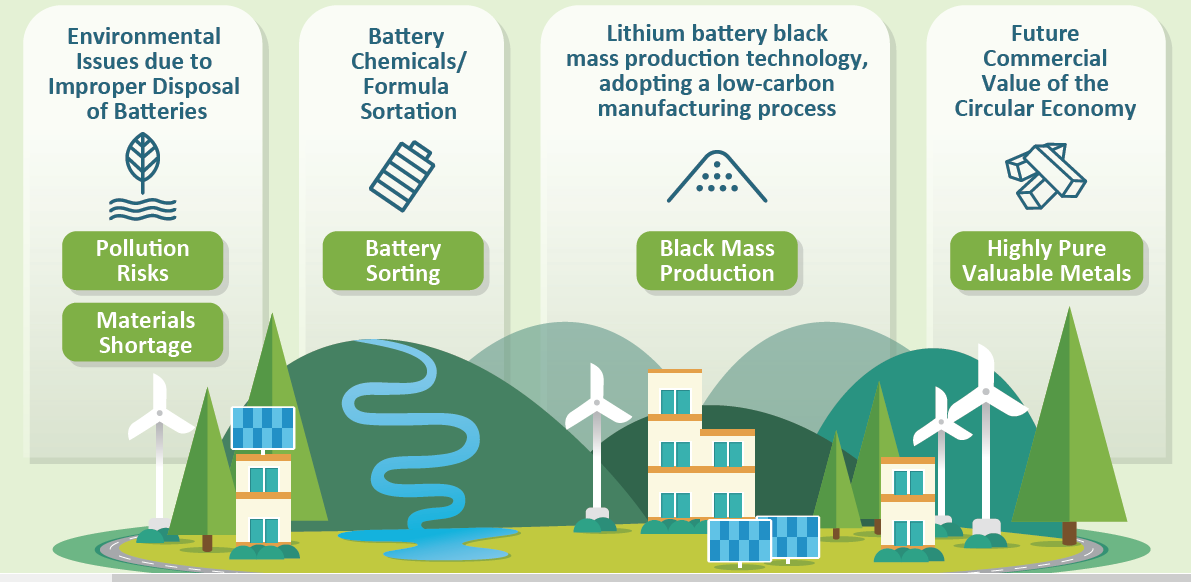

Statistics by the Ministry of Environment indicate that Taiwan is expecting to have 1,100 metric tons of waste lithium batteries annually starting from 2025. Lithium batteries

contain significant amounts of lithium, cobalt, nickel and other valuable metals. Improper disposal or treatment of these waste lithium batteries could lead to severe environmental pollution. In addition, mining these metals will further aggravate the natural ecosystem. Therefore, only by recycling these materials can we achieve environmental sustainability, which highlights the importance of the recycling technology in the future and the urgency of the demand for raw materials. Facing such challenges, Wistron GreenTech Texas began its research and development for key technologies and equipment, with the focus on the production technology of black mass, a key element of lithium battery recycling.

The key behind the R&D of this innovative equipment was the safe and effective treatment of waste lithium batteries, prevention of waste gas and wastewater pollution during the treatment process and mitigation of fire and explosion risks. Wistron initiated a 16-week project with the Commercialization and Industry Service Center and Material and Chemical Research Laboratories under Industrial Technology Research Institute to formulate a blueprint for their lithium battery business. Meanwhile, Wistron collaborated with equipment developers to discuss the details of Wistron's unique requirements, from the purity testing of recycled black mass to the necessary safety certifications.

Wistron and its external partners utilized innovative technologies building the lithium battery recycling line, which covers consumer electronics, EV battery modules and line scrap materials from battery production. This facility has the capacity to process up to 1,000 metric tons of scrap batteries and production remnants. This system is expected to complement the company’s existing cathode direct recycling line to form a comprehensive recycling network. Not only will this further help Wistron meet its lithium battery recycling goal and create a new revenue stream while offering Wistron’s green value proposition to the clients. Wistron will continue to devote resources to developing advanced recycling technologies and equipment, and serve as the locomotive for the circular economy trend.

contain significant amounts of lithium, cobalt, nickel and other valuable metals. Improper disposal or treatment of these waste lithium batteries could lead to severe environmental pollution. In addition, mining these metals will further aggravate the natural ecosystem. Therefore, only by recycling these materials can we achieve environmental sustainability, which highlights the importance of the recycling technology in the future and the urgency of the demand for raw materials. Facing such challenges, Wistron GreenTech Texas began its research and development for key technologies and equipment, with the focus on the production technology of black mass, a key element of lithium battery recycling.

The key behind the R&D of this innovative equipment was the safe and effective treatment of waste lithium batteries, prevention of waste gas and wastewater pollution during the treatment process and mitigation of fire and explosion risks. Wistron initiated a 16-week project with the Commercialization and Industry Service Center and Material and Chemical Research Laboratories under Industrial Technology Research Institute to formulate a blueprint for their lithium battery business. Meanwhile, Wistron collaborated with equipment developers to discuss the details of Wistron's unique requirements, from the purity testing of recycled black mass to the necessary safety certifications.

Wistron and its external partners utilized innovative technologies building the lithium battery recycling line, which covers consumer electronics, EV battery modules and line scrap materials from battery production. This facility has the capacity to process up to 1,000 metric tons of scrap batteries and production remnants. This system is expected to complement the company’s existing cathode direct recycling line to form a comprehensive recycling network. Not only will this further help Wistron meet its lithium battery recycling goal and create a new revenue stream while offering Wistron’s green value proposition to the clients. Wistron will continue to devote resources to developing advanced recycling technologies and equipment, and serve as the locomotive for the circular economy trend.