【Recycling】The Key to Solving the World's Millions of Retired Electric Vehicle Batteries - Recycling and Reuse of Lithium Batteries

Wistron Takes the Lead in Investing in Start-ups in Lithium Battery Recycling

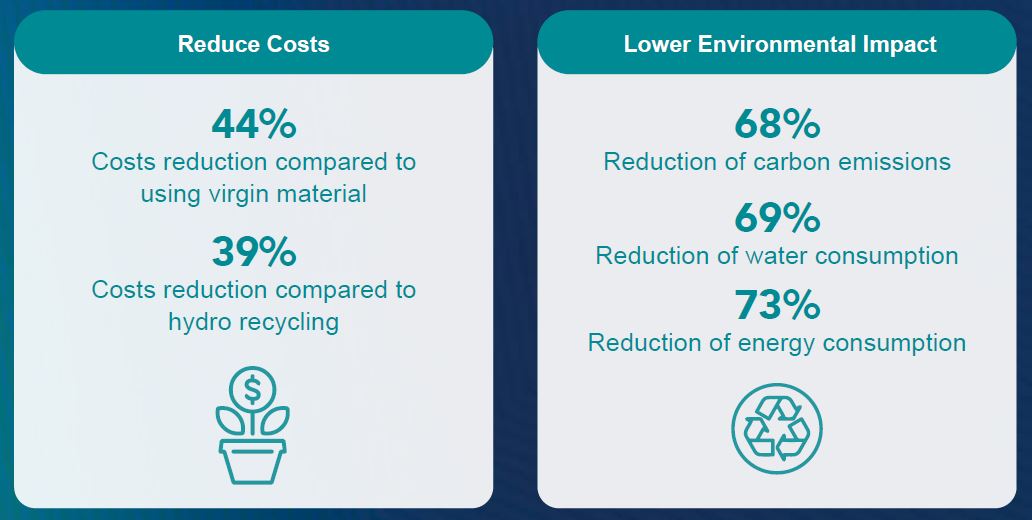

In 2020, Wistron GreenTech Texas began to pay attention to and seek the recycling of lithium batteries - a new technology for the recycling of cathode materials. In 2021, an agreement was signed with our technical partner. We utilized the patented technology, direct recycling and refining of lithium batteries, to recycle lithium batteries from both consumer electronics and electric vehicles. According to the EverBatt data of Argonne National Laboratory in the United States, this technology can reduce water consumption by 69%, energy consumption by 73%, and greenhouse gas emissions by 68% compared with cathode materials refined by virgin (raw) materials.

Establishment of Lithium Battery Recycling Production Line

The trial production line for recycling and refining lithium battery cathode materials was set up in Wistron Green Tech (Texas) in 2022. The trial production is expected to be officially launched in 2023, and the target is to implement an annual production capacity of 500 metric tons in 2025. After the new technology reaches the mass production target, and the output of the positive electrode material meets the industrial grade of battery manufacturing, Wistron Green Tech (Texas) will formulate a plan for future plant expansion, and continue to work with partners to establish a lithium battery recycling and refining plant with greater processing capacity to solves the environmental problems of global battery production and recycling, and becomes a new growth momentum for the development of Wistron's circular economy.